Our Services

| Materials | Aerospace Grade Epoxy Adhesive Elevated Temperature Curing High Service Temperature Structural Paste Adhesive |

| Curing Method | Oven |

| Cure Rate | 1 Hour |

| Cure Temperature | >200° F |

| Surface Temperature - Retains Adhesive Properties To: | 450° F 100 psi / 6.9 MPa ASTM D1002 |

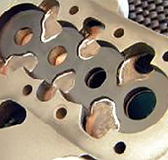

| Applications | Oil Pump |

| Adhesive Form | Thixotropic Paste |

| Pot Life | 8 hours (Room Temperature) |

| Adhesive Features | High Temperature Compatible with Aerospace Fluids Oil Resistant |

| Cleaning | Finish No. 4.1 Grit Blasting Finish No. 4.2. Hot Alkaline Cleaning Finish No. 4.3 Solvent Cleaning Blending Procedures (GE Standard Practices Manual 70-42-00) Light Duty Alkaline Cleaning (GE Standard Practices Manual 70-32-03) |

| Inspection | Coordinate Measuring Machine (CMM) Fluorescent Penetrant Inspection (FPI) SAE-AMS-STD-2175 Method 5.3.1 (Visual) Method 5.3.2.2 (Penetrant) ASQ-Z1.4 & ASQ – Z1.9 ISO-10012 & ANSI-Z540.3 Spot Fluorescent Penetrant Inspection (GE 70-32-03) |

| Testing | Certified Level II NDT Liquid Penetrant Non Destructive Testing (Mil-HNBK-728/1) |

| Quality Program | FAA 14 CFR Part 145 Compliance |

| Documentation | FAA Form 8130-3 (Airworthiness Approval Tag) |

| Additional Services | Repair Process Development Designated Engineering Representative (DER) |

| Production Volume | 1 to 30 parts |

| Typical Lead Time | 2 to 4 weeks |

| Industry Focus | Aerospace Military Commercial |

| Intended Applications | Turbine Components Oil Pump Components Fuel Pump Components Check Valve Assemblies |

| Air Agency Certification | FAA R91R0970 - Federal Aviation Administration EASA.145.5316 - European Aviation Safety Agency |

| File Formats | Modeling Capabilities |